Last updated on December 20th, 2025 at 07:29 am

I have to confess, two weeks ago I thought digital twins were basically a hype-friendly term for fancy 3D models. It was then that my team tasked me with investigating if we really should be investing in this tech for our product range. What I discovered shifted my entire perspective on product development.

Table of Contents

What Digital Twins Actually Are

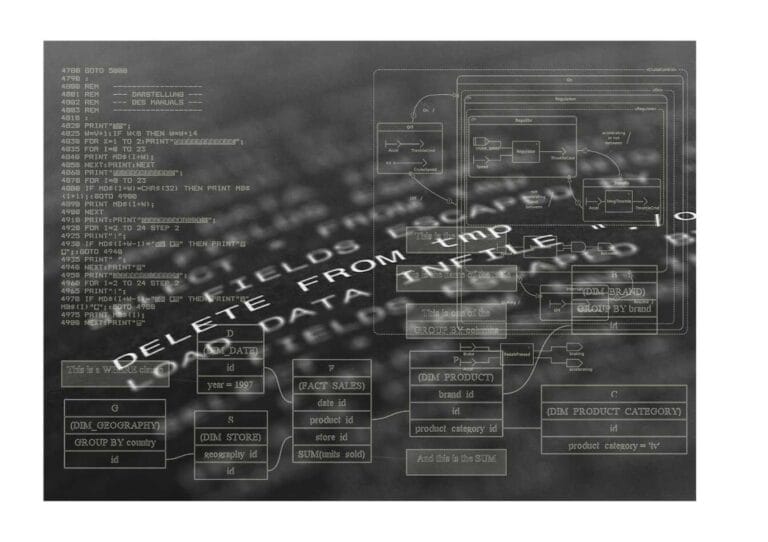

Here’s what clicked for me: a digital twin is not only a static simulation. It is a digital twin that continually mirrors the physical product with live data. Think of it as your phone streaming its content to your laptop, only it’s not just the one feature on the product you’re watching, but instead your whole product projected through data returning performance information in a virtual version that learns and predicts what will happen next.

The difference matters. Traditional simulations are one-and-done tests. Digital twins? They’re living models, and they get smarter as your product works in the real world.

Why Companies Are Going All-In

The numbers surprised me. The market’s expected to leap from $24.5 billion in 2025 to $259.3 billion by 2032. That’s not hype that is actual money being laid down. And 69 percent of manufacturers are already using digital twins, while another 85 percent plan to within the next year or two.

Why the rush? The benefits are measurable. Businesses say they reduce develop ment time by 20 to 50 percent, which translates into getting products faster to market. Quality problems fall 25% once products reach production, and products developed with digital twins sell 35% more because they are just better designed.

I’ll be honest, this is where it got my attention: some companies cut back on 2-3 physical prototypes because of the printer. That’s huge cost savings and time return.

The Real-World Applications

I took a closer look at how teams are actually putting this technology to work. Virtually everything is tested in product design, aerodynamics, thermal qualifications and structural integrity before anything is every fabricated. Gone are the days of waiting weeks for a prototype only to learn the cooling system doesn’t work.

Information taken from sensors on products already in the field is fed back into digital twins to predict when equipment would fail and plan for optimal maintenance schedules. Tesla does this masterfully taking real-time data from digital twins associated with its vehicles to optimize battery health and thermal performance, and pushing out software updates based on what they learn.

The sustainability angle matters too. Teams can evaluate environmental impact and material usage optimization even before production begins.

The Challenges Nobody Talks About Enough

Here’s where it gets real. For most companies, the costs of implementation are between $500,000 and $2 million. That covers sensors, software licenses, cloud computing and training your team. For smaller companies, that can be a bitter pill to swallow.

Security worries me at night. Digital twins require a lot of sensitive information manufacturing processes, proprietary designs, the works. More IoT endpoints mean more vulnerabilities, and you are essentially making a digital copy of your entire operation that can potentially be compromised.

Then there’s the integration headache. Older equipment does not have the sensors and connectivity that it needs. Information gets stuck in silos, decreasing how useful your digital twin really is. And 78 percent of companies say data integration is one of their biggest challenges so you won’t be alone if your systems don’t work well together.

What I’d Tell Someone Starting Out

If your team is thinking about digital twins, don’t expect to boil the ocean right away. Begin with individual product lines that have a clear value proposition, use phased iteration to deal with tech hurdles up front and then gradually expand.

The good news? You don’t have to have shiny new infrastructure, although digital twins can be grafted onto existing systems, albeit usually with some upgrades. For targeted implementations, some organizations achieve productivity gains and costs reduction in as few as 6-12 months.

You’re going to need the right skills on your team. Skills in data analytics, IOT system management and simulation modelling are key. For most companies, a blend of upskilling existing staff and bringing in specialized employees is what’s needed.

The Bottom Line

Here’s my take after diving into all this research: Digital twins are no longer a nice-to-have. Executives agree: 97% of c-suite leaders say that digital twin capabilities are essential to their business’s future success. The tech is maturing quickly, prices are dropping and the competitive edge is real.

Is it right for your team? It depends on your product complexity, budget and timeline. But if you’re creating physical products that work in the real world, it’s worth looking into. Run little tests, measure everything and scale what works.

At least that’s what I’m telling my team.

I’m a technology writer with a passion for AI and digital marketing. I create engaging and useful content that bridges the gap between complex technology concepts and digital technologies. My writing makes the process easy and curious. and encourage participation I continue to research innovation and technology. Let’s connect and talk technology!