Last updated on December 20th, 2025 at 06:44 am

The first time I heard “digital twin,” I assumed it was the product of another techie buzzword generator. Like blockchain, or metaverse, you know? Something companies bandy about to try and sound cool.

So then I figured out what it actually is, and here’s the thing: this tech is already altering how stuff goes down around you, whether you know it or not.

Table of Contents

So What Is a Digital Twin, Exactly?

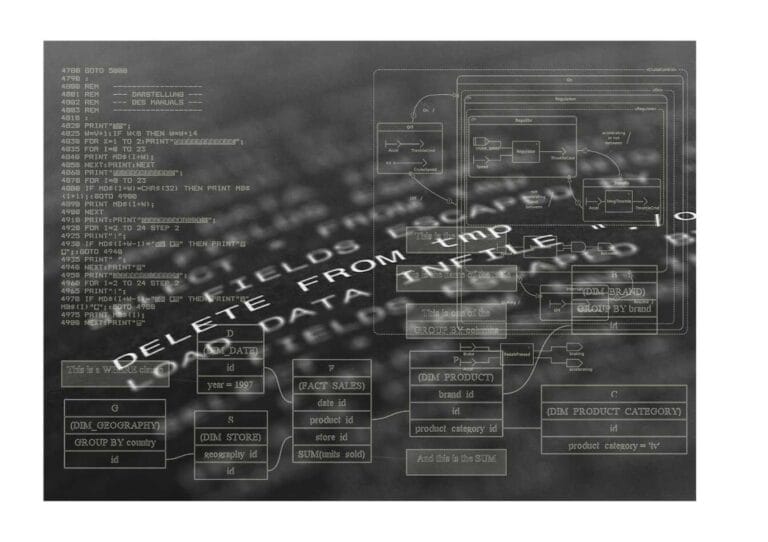

Think of it this way: imagine that you made a virtual copy of something in real life a machine, a building, maybe even your own heart and it could update at every moment. Not a 3D model that just sits in the lap and looks shiny. I mean an immediate copy corresponding to what is happening to the thing now.

Digital twin A digital twin is a virtual model of an object, system, or process that enables its characteristics and performance to be measured in real time. The key difference? It’s connected. Sensors continually provide it with data, so if something changes in the real world, a digital shadow of that world learns instantly.

Here’s how they differ from traditional simulations: Simulations operate on an assumed set of parameters and don’t update in response to real-world changes, but digital twins sync with physical assets constantly using real-time data. “It’s the difference between a photograph of your house and real time security cameras one is a still picture, you’re capturing two or three times per second the other is in real time.”

Where This Gets Interesting

Once I knew what to look for, I began seeing digital twins everywhere. Tesla? They generate digital twins of every car they manufacture, capturing real-time operating data to enhance performance and fuel software updates. That’s how they solve problems or add features without you setting foot in a service center.

Hospitals are using them too. Surgeons print 3D patient anatomy and conduct rehearsals of surgery in preparation for complex procedures. Consider that – your surgeon can virtually practice on you first.

And it’s not just high-tech stuff. At London Heathrow Airport, digital twin technology is analysing ground operations and has helped reduce CO₂ emissions by 30,000 tonnes per annum. That’s real impact.

Why Should You Care?

This is where it gets : this isn’t about robots, not sci-fi futures. It is for repairing errors before they become an issue.

Manufacturers employing digital twins can increase their productivity by 30-60 percent and decrease material waste by around 20. That could allow for cheaper products, less environmental damage and less stuff that breaks all the time.

For cities, digital twins enable officials to track infrastructure usage in real time, simulate responses to disasters and manage traffic. Translation: fewer potholes, improved emergency planning and less time stuck in traffic.

Even retail’s getting in on this. Some companies build “digital twins of customers” that mimic buying behavior as a way to experiment with marketing campaigns before they go live. Through doing it this way, we had one retailer who saw 20% better campaign results. You’re just receiving ads that are more relevant versus random spam.

The Honest Truth About Challenges

It’s not all smooth sailing. It can be very expensive to implement, between $500,000 and $2 million for most projects, which is why you see big companies trying it out first. And 78% of companies say data integration is one of their biggest hurdles getting all those sensors and systems to speak the same language isn’t easy.

Security’s another worry. Digital twins are dependent on continuous data streams from various sources, and that has lead to multiple attack vectors with ransomware encountered as a viable threat to business operations. If someone hacks your digital twin, they might be able to mess with the real you.

What’s Coming Next

The really wild part? AI is shortening it from six months down to weeks, and the technology can now automatically produce code for digital twins. Which means smaller businesses may even be able to afford this soon.

Virtual and augmented reality is changing the way people engage with digital twins engineers can physically enter virtual versions and gesture to move items around. We’re getting those Iron Man-level interfaces for real.

Bottom Line

Digital twins are not a replacement for the physical world they’re about to make it better. From the car you drive to the buildings in which you spend your days, this technology is quietly making things more efficient, more environmentally friendly and less likely to break when you need them most.

The market is on board: Worth $24.5 billion in 2025, it’s estimated to reach $259.3 billion by 2032. That’s not hype that is real money betting on actual outcomes.

Whether you’re a business owner pondering if this is relevant to you, a student working through the career options or just curious about where tech’s going, digital twins are something worth knowing about. They’re already here. They’re already working. And they’re just getting started.

I’m a technology writer with a passion for AI and digital marketing. I create engaging and useful content that bridges the gap between complex technology concepts and digital technologies. My writing makes the process easy and curious. and encourage participation I continue to research innovation and technology. Let’s connect and talk technology!